In today’s age of personalization and innovation, customization has become a vital part of retail and manufacturing industries. Among the latest advancements driving this trend is UV DTF wraps, a game-changing technology that offers unparalleled versatility, quality, and ease of use. Whether you’re an entrepreneur, designer, or just curious about cutting-edge printing solutions, understanding UV DTF wraps is crucial. This guide will take you through everything you need about this revolutionary technology.

What Are UV DTF Wraps?

UV DTF stands for Ultraviolet Direct-to-Film. It is a printing method where designs are directly printed onto a specialized film using UV-curable inks, and then transferred to a target surface. The term “wraps” refers to the ability of the printed film to adhere seamlessly to a wide variety of materials, including curved or textured surfaces, providing a highly customizable decorative solution.

Unlike traditional heat transfer or sublimation printing, UV DTF eliminates many of the limitations these methods face, such as material restrictions or poor adhesion on complex shapes. This makes UV DTF wraps a preferred choice for industries looking for high-quality, durable, and visually stunning customizations. Whether you are customizing cups, phone cases, or even larger industrial products, UV DTF ensures vibrant, long-lasting results that can withstand wear and tear.

How Does the UV DTF Process Work?

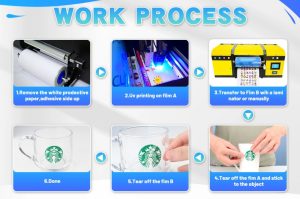

The UV DTF process is straightforward yet powerful, combining advanced technology with user-friendly execution. Here’s a step-by-step breakdown of how it works:

- Design Preparation:

The process begins with creating a digital design. Specialized software is used to ensure the design matches the desired dimensions and maintains high resolution for optimal print quality. This can involve fine-tuning color schemes, details, and ensuring the design fits the shape of the object. - Printing on Film:

Using a UV DTF printer, the design is printed onto a transfer film. UV inks are applied layer by layer, and each layer is cured instantly by UV light during printing to produce vibrant colors and sharp details. This is one of the key benefits of UV DTF — the prints are dry as soon as they come off the printer, preventing smudging or any need for drying time. - Adhesion to the Target Surface:

The printed film is then applied to the desired surface, such as a phone case, tumbler, or piece of equipment. The adhesive layer ensures a secure bond between the film and the object, even on uneven or curved surfaces. The film can be carefully positioned and adjusted before securing it firmly. - UV Curing:

A final curing process with UV light ensures the ink is fully hardened and bonded, enhancing the durability and scratch resistance of the design. This is a crucial step as it ensures the longevity of the design, making it resistant to water, UV exposure, and everyday handling.

This combination of precision printing and strong adhesion makes UV DTF wraps a versatile solution for countless applications, from custom product designs to industrial branding.

Benefits of UV DTF Wraps

UV DTF wraps bring numerous advantages over other printing methods. Here’s why they stand out:

- Exceptional Print Quality:

UV DTF produces vibrant colors, sharp details, and excellent opacity. The curing process locks in the design, ensuring it remains vivid and eye-catching for years. Unlike traditional printing, which may fade or lose detail over time, UV DTF prints are designed to withstand constant exposure to light and wear. - Durability:

Prints made with UV DTF are resistant to water, UV light, scratches, and general wear and tear. This makes them ideal for products exposed to harsh environments or frequent use. Whether it's a cup that gets washed multiple times a day or a branded tool that undergoes daily handling, UV DTF prints retain their quality and appearance. - Versatility:

UV DTF wraps can adhere to a wide range of surfaces, including plastic, metal, glass, wood, and even leather. Their flexibility allows them to conform to flat, curved, and irregular shapes with ease. This makes UV DTF wraps ideal for custom printing on a variety of consumer products, from mugs to industrial machinery. - Ease of Use:

Compared to other methods, UV DTF involves fewer steps and requires less technical expertise. This makes it accessible for small businesses and startups looking to offer high-quality customizations. You don't need a huge staff or years of experience to start using UV DTF printing — it’s efficient and intuitive. - Customization at Scale:

Whether you’re producing a single personalized item or a large batch, UV DTF wraps make it easy to switch designs and maintain consistent quality. This makes it perfect for both small runs of custom products and large production runs in industries that require high output.

Applications of UV DTF Wraps

UV DTF wraps are transforming industries by enabling limitless customization. Here are some of their most common applications:

- Retail and Gifts:

Custom phone cases, tumblers, mugs, and keychains are among the most popular items customized using UV DTF wraps. Personalized gifts for birthdays, weddings, and corporate events can be produced with ease, helping businesses in the retail sector stand out with unique offerings. - Industrial Branding:

Logos and labels can be printed on equipment, tools, and machinery, creating long-lasting brand marks that resist wear and tear. Durable markings for automotive parts or electronic devices ensure that the branding stays intact throughout the lifecycle of the product. - Creative Industries:

Artists and creators use UV DTF wraps to produce artistic décor, wall art, and furniture embellishments. This method allows for high-quality prints on various surfaces, including wood, glass, and even textured materials. - Specialized Applications:

UV DTF is used in medical devices requiring durable and precise labeling. Aerospace and automotive components with unique branding needs also benefit from the durability and flexibility that UV DTF offers, ensuring that important information stays intact.

From small businesses to large-scale manufacturers, UV DTF wraps are unlocking new possibilities in design and functionality, offering high-end, long-lasting results for virtually any surface.

UV DTF vs. Other Printing Techniques

When comparing UV DTF to other popular printing methods, the differences become clear:

| Feature | UV DTF Wraps | Heat Transfer | Sublimation Printing | UV Direct Printing |

| Material Compatibility | Broad (plastic, metal, wood, glass) | Limited (mostly fabrics) | Limited (polyester) | Broad |

| Durability | High | Moderate | Moderate | High |

| Surface Flexibility | Adheres to curves/textures | Flat surfaces only | Flat surfaces only | Mostly flat |

| Setup Cost | Moderate | Low | Moderate | High |

UV DTF stands out for its versatility, quality, and ability to adapt to various shapes and materials. This makes it ideal for businesses that need to print on a variety of products and surfaces, offering more options than heat transfer or sublimation.

Choosing the Right UV DTF Solution

If you’re considering UV DTF wraps for your business, here are some tips:

- Assess Your Needs:

Determine the volume and type of products you’ll be customizing to choose the right equipment and materials. If you plan to print on a wide range of surfaces, ensure your printer can handle various substrates effectively. - Invest in Quality Equipment:

Reliable UV DTF printers and high-quality inks are essential for consistent results. The printer should support the specific size and material of your products to ensure precision and quality. - Plan for Training and Maintenance:

While UV DTF is user-friendly, ensuring your team is trained on the equipment can help avoid errors and maximize productivity. Regular maintenance is also necessary to keep your printer in top condition. - Target the Right Markets:

From promotional products to industrial branding, identify niches where UV DTF can provide unique value. Consider targeting the personalized gift market, or industries like automotive, where durable prints are crucial.

Future Trends in UV DTF Wraps

As technology evolves, UV DTF wraps are expected to become even more versatile and accessible. Future developments may include:

- Advanced Inks and Films:

Improved materials for greater durability, eco-friendliness, and special effects like holographic finishes. These advancements will allow businesses to offer even more unique designs with an emphasis on sustainability. - Integration with AI and IoT:

Automated design generation and real-time monitoring of printing processes will make UV DTF more efficient and accessible. AI can help in predicting ink usage and reducing waste, making the process more cost-effective. - Broader Applications:

The potential for UV DTF wraps to expand into architectural elements, wearable tech, and smart surfaces is vast. As industries continue to explore innovative ways to integrate custom designs, UV DTF will play an essential role.

Conclusion

UV DTF wraps are more than just a printing method—they’re a gateway to limitless creative possibilities. Combining vibrant quality, unmatched durability, and incredible versatility, this technology is empowering businesses and creatives alike.